The Farm and Family Fair 2025

I’m going to start with these two pictures below because when I think of this fair I simply think, “I had such a good time.” And I think these pictures…

Share

MACHE in Duluth

We pulled back up our lane last night around 10:30, hearts full after an incredible two days at the Minnesota Association of Christian Homeschool Educators (MACHE) conference. Rory was invited…

Share

Awesome and Wonderful, part 2

It was 2019 when I took Ivar to A&W and told him right then that I wanted to take him to A&W once a month. We had such a fun…

Share

The Homesteading Conference in Texas

We hit the road right after Easter. Just one road, really. Highway 35, to be exact. We stayed on that road right into Texas for a wonderful weekend at the…

Share

A Day at Blissful Bee Pastures

Two years ago we hosted a maple syruping workshop at our farm, teaching the basics of tapping maple trees and evaporating maple syrup. One of the families that attended this…

Share

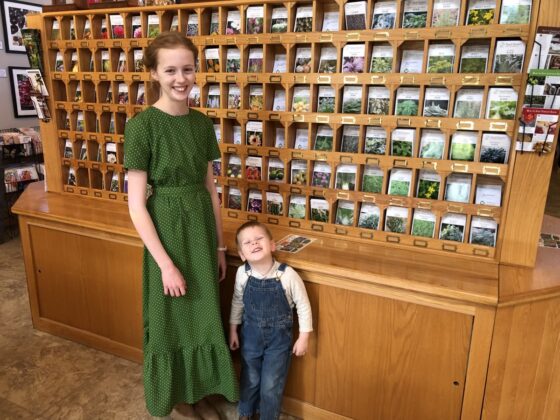

Field Trip to Seed Savers

We took a beautiful two-hour road trip, south on highway 52, and found ourselves at Seed Savers in Decorah, Iowa. As a garden-loving family, this was basically our family’s idea…

Share